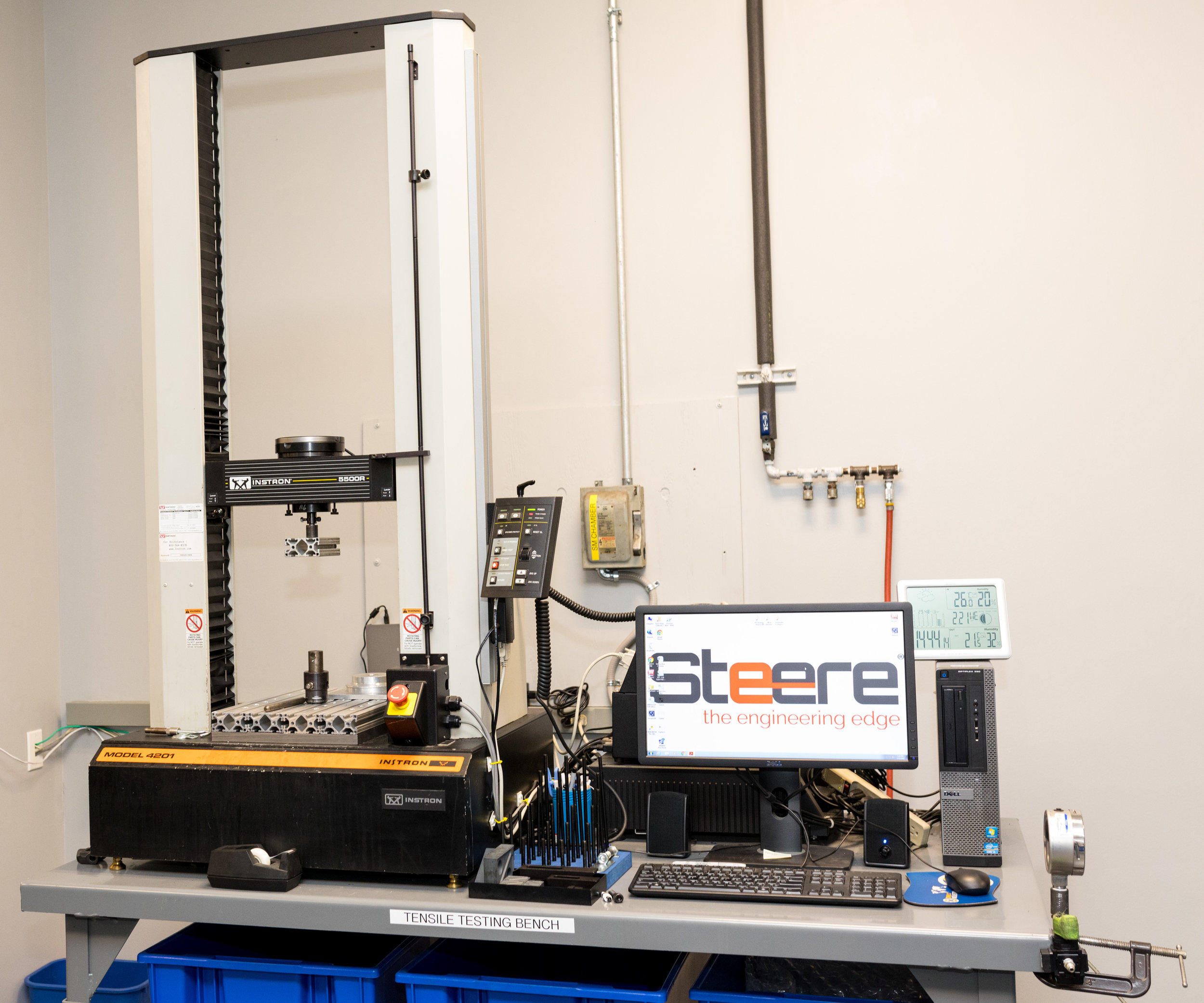

Quality Control

"PURSUING EXCELLENCE THROUGH TOTAL QUALITY, CUSTOMER RESPONSIVENESS AND CONTINUOUS IMPROVEMENT, WHILE MEETING ALL REQUIREMENTS"

STEERE's commitment to quality is apparent at every level and area of the organization. We firmly abide by the principle that everyone is responsible for driving quality, from the operator who produces the part to the engineer who designs the equipment to the manager who audits the procedures. Using a cross-functional team approach, STEERE continually strives to improve both the quality and efficiency of our products and processes, resulting in superior performance and elevated customer satisfaction.

STEERE utilizes standard industry tools such as APQP, FMEA and PPAP in order to ensure products are not only launched successfully, but continue to perform at zero defect levels throughout production. We support customer capacity analysis activities including Run@Rate and Production Demonstration Runs (PDRs). STEERE has integrated Lean concepts into our operations including cell balancing, standardized work methods, waste elimination and 5S. Moreover, we have deployed error-proofing measures throughout the various processes in an effort to prevent defects rather than contain them.

Environmental Policy

Steere Enterprises, Inc. is committed to complying with environmental legislation, regulations, and all other requirements to which we subscribe. We are committed to preventing pollution, continually improving our environmental performance and being a good community citizen.